|

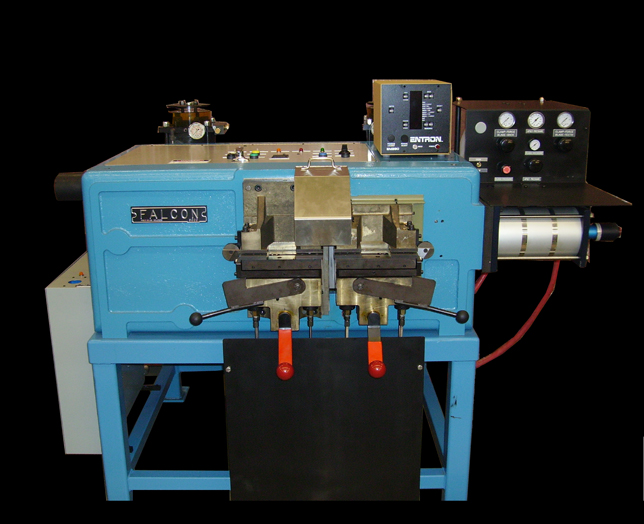

Falcon Precision Machining Company’s FW-5000 welder is a free standing air/electric operated machine capable of welding 1” x .035”

To 3-1/8’’ x .063” carbon and Bi-metal band saw material. This extra heavy-duty production orientated machine is designed to make strong and accurate welds of large bands. Falcon can also help you with machine and welding service along with a full line of replacement parts.

SPECIFICATIONS

POWER SUPPLY: 240 VAC single phase, 60 Hz. 50 Hz and 380-480 VAC available at special request.

TRANSFORMER: 34 KVA with 8-position voltage control.

UPSET FORCE: Variable 1,000-5500 lbs.

AIR SUPPLY: 20 c.f.m. at 85 p.s.i.

DIMENSIONS: 74” / 1.9 m long x 59” / 1.5 m high x 54” / 1.37m deep, including external controls.

BLADE CAPACITY: Carbon and Bi-metal 1” x .035” (25.4 mm x .89mm) to 3.125” x .063”

(80 x 1.6 mm)

SHIPPING WEIGHT: 2,700 lbs. / 1,215 kg.

FEATURES

The FW-5000 is a self-standing super heavy-duty welder capable of welding a variety of large bands.

All controls are conveniently mounted and easy to operate. A three stage upset cylinder provides a variable

forging force adjustable through a precision pressure regulator and selector valve. A solid state

programmable weld / anneal control provides precise control of weld and anneal current. It’s two-stage

annealing cycle, and ease of adjustment, allows precise “on the fly” adjustability. This handy feature is a

must for proper annealing. The air assisted parabolic flashing cam starts slowly, and then accelerates to

reach maximum speed at the weld’s completion to produce strong and uniform welds. The special cam

Drive system provides smooth and constant cycling with upset pressures as low as 1,000 lbs. A Quick-

change link pin system provides a three-position jaw spacing positions change (internal) to permit a fast,

easy adjustment for different blade widths. Three sets of back-up alignment sets are included. A circular

set for most tooth forms and two rectangular sets for multi-height and other course tooth forms. A 2” /

51 mm main shaft and linear ball bushings provide smooth stable operation and positive blade alignment.

Manual pre-clamp with a dual stage air / hydraulic assist deliverer’s positive blade clamping up to 21,000

Lbs. along with easy heat pattern control. Other features include semi-automatic platen advance and

retract, integral welder stand and blade hanging rack, built in flash timer and an automatic electric shut off

safety feature.

|

|

|